**** TSB Release

Marine transportation safety investigation report M19A0025

Sinking and loss of life

Workboat Captain Jim

Approximately 4 NM southeast of Halifax Harbour, Nova Scotia

Summary

On 29 January 2019, the workboat Captain Jim, with 2 crew members and 1 passenger on board, began taking on water and became disabled 2.8 nautical miles from its home port of Eastern Passage, Nova Scotia. A short time later, the vessel sank rapidly. One of the crew members and the passenger managed to board the vessel’s life raft. They were rescued by a Halifax Harbour pilot boat and taken to Halifax, Nova Scotia. Divers located the body of the other crew member inside the vessel’s wheelhouse later that day.

1.0 Factual information

1.1 Particulars of the vessel

| Name | Captain Jim |

|---|---|

| Official number | 328374 |

| Port of registry | Saint John, NB |

| Gross tonnage | 14.78 |

| Type | Workboat |

| Materials | Reinforced plastic |

| Registered length | 11.37 m |

| Built | 1989 |

| Propulsion | 1 diesel engine providing 158 kW |

| Maximum complement | 14 (maximum 12 passengers, minimum 2 crew) |

| Registered owner | RMI Marine Limited |

1.2 Description of the vessel

The Captain Jim was purchased by RMI Marine in 2004 for use as a multi-purpose workboat and was operated primarily as a passenger vessel for transporting people to work sites (Figure 1). The wheelhouse was equipped with electronic equipment consisting of 2 very high frequency (VHF) radiotelephones, a radar, a chart plotter and a global positioning system. There were floodlights and 2 life rafts on top of the wheelhouse at the time of the occurrence.

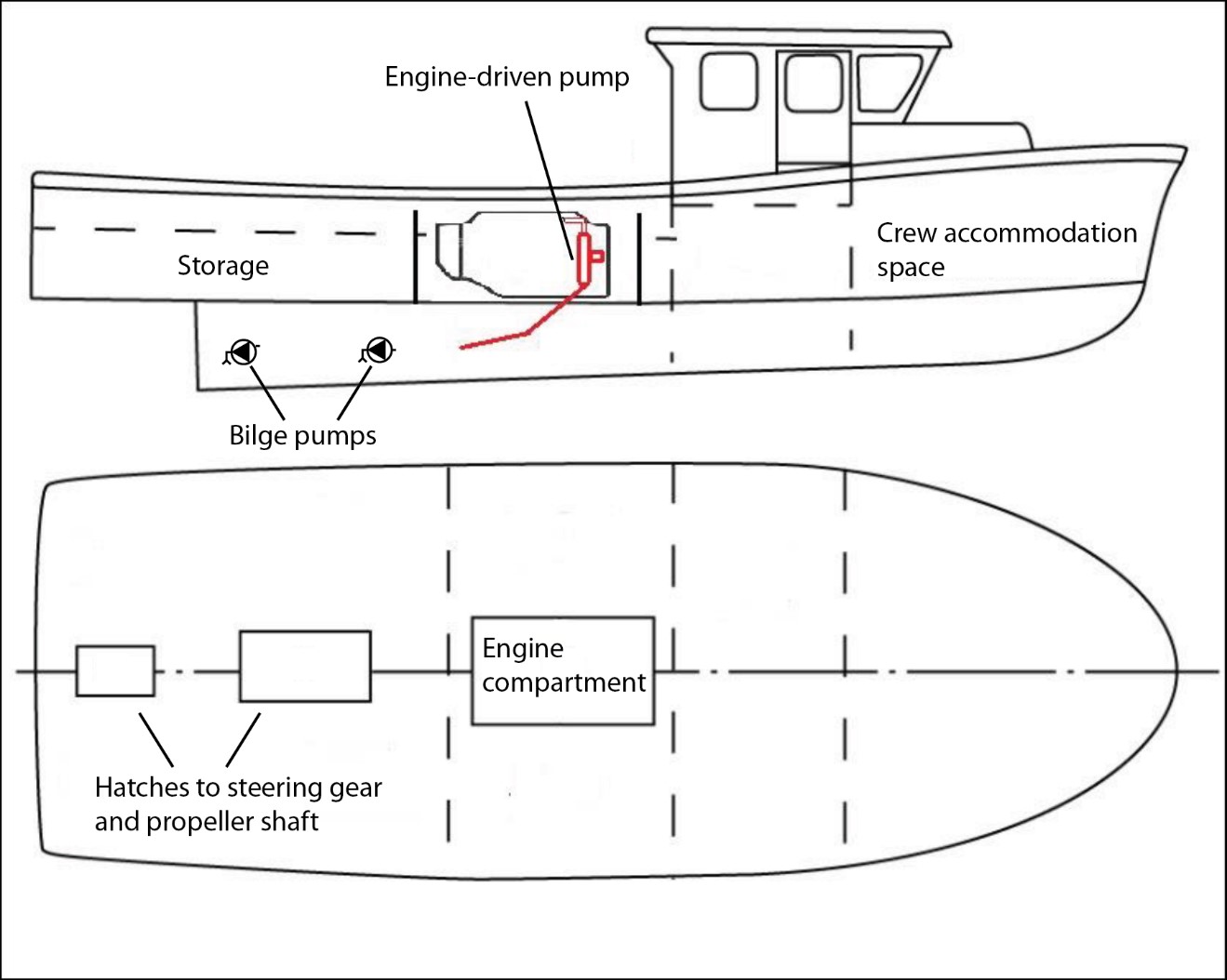

There were 4 hatches and a raised coaming around the engine compartment (Figure 2). Since the Captain Jim was an undecked vessel, the hatches and coaming were designed to be weathertight, but not watertight, and water that entered the vessel accumulated in the bilge.

The vessel was fitted with 2 electric bilge pumps and 1 engine-driven pump. One bilge pump was located forward, in the engine compartment, and was set to activate automatically if triggered by a float switch in the bilge. The other bilge pump was located aft, in the lazarette, and was activated manually using a switch in the wheelhouse. The engine-driven pump was located in the engine compartment (Appendix A). It was designed to be used as a firefighting pump to assist other vessels but was generally used as a washdown pump for cleaning the deck; it could also be used to pump the bilge.

The port and starboard sides of the vessel each had 3 freeing ports, installed in July 2008, with hinged aluminum flaps. Subsequently, a securing arrangement was installed on each freeing port to allow the aluminum flaps to be fastened shut (Figure 3). The workboat also had 2 scuppers just aft of the stern-most freeing ports. The scuppers could be fitted with screw plugs but were normally left open.

1.3 History of the voyage

At approximately 2145Footnote1 on 28 January 2019, the Captain Jim departed the RMI Marine dock in Eastern Passage, Nova Scotia, with the master, a deckhand, and a passenger on board. All 3 were wearing personal flotation devices. The purpose of the voyage was to transport the passenger to an oil tanker anchored in the approaches to the Halifax Harbour, where he was taking samples of the cargo, and then return him to Eastern Passage. The trip was approximately 7 nautical miles (NM) each way.

At approximately 2240, the Captain Jim arrived alongside the tanker. The deckhand had begun assisting the passenger to board the tanker with the sampling equipment when the deckhand aggravated a pre-existing back injury. While the passenger was working on the tanker, the Captain Jim drifted nearby and the master ordered the deckhand to rest on the settee in the wheelhouse.

At approximately 0135 on 29 January, the passenger completed his sampling and re-boarded the Captain Jim with the assistance of the master. The Captain Jim then proceeded back to Eastern Passage on a northerly course. The seas were 1 to 2 m, with winds from the northeast.

Just before 0150, the visual indicator for the automatic electric bilge pump began to light up intermittently, indicating that the bilge pump was turning on and off. After about a minute, the visual indicator lit up and remained on, indicating that the bilge pump was running continuously. At approximately 0152, the high-water bilge alarm sounded. The master then started the second electric bilge pump.

The master also turned on the vessel’s floodlights, and the master and passenger observed that approximately 20 cm of water had accumulated on the back deck. At this time, the vessel was nearing calmer water. The master continued navigating toward the calmer water at 10 knots for a few minutes before checking the water level again, when he noticed through the back window of the wheelhouse that the securing arrangement for the starboard forward freeing port was not in place and that the wave action was causing surges of water to enter the vessel through the open freeing port.

The master continued navigating until 0207, when the vessel’s engine was overcome by water and stopped. The vessel was just outside of calm waters. The water level had risen to approximately 40 cm at the stern (Figure 4).

The VHF radiotelephone was no longer operational, as the water level had risen above the vessel’s batteries. At 0208, the master used his cellphone to call Marine Communications and Traffic Services (MCTS) Halifax and report that the vessel had developed a problem with one of the freeing ports, had taken on water, and had lost its engines. The master asked about the availability of nearby vessels in the area. When asked if he was in immediate danger, the master replied that there was a possibility the vessel could sink and that the whole back deck was awash. At 0213, MCTS Halifax relayed the message to the Joint Rescue Coordination Centre (JRCC) in Halifax. Around this time, the master also reported the situation to the company.

At 0215, MCTS Halifax issued an urgency broadcast requesting assistance for the disabled Captain Jim but did not receive a response. MCTS then contacted a Halifax Harbour pilot boat and a tug directly by VHF radiotelephone and requested that they proceed to the Captain Jim. At 0216, JRCC contacted the master for an update, but the call went to voicemail. The master and the passenger lowered one of the vessel’s life rafts from the top of the wheelhouse into the water on the port side of the vessel and inflated it in preparation to abandon the vessel if necessary. The master and the passenger then returned to the wheelhouse where the deckhand was resting. The master continued to monitor the water level through the back window of the wheelhouse.

At 0226, JRCC contacted the master on the Captain Jim to inform him that a Canadian Coast Guard vessel and the pilot boat were on the way to assist the crew. The master informed JRCC that the vessel’s back deck was submerged to the gunwale and that everyone on board would likely be in the life raft by the time assistance arrived.

At 0228, MCTS Halifax issued a distress broadcast requesting that nearby vessels assist the Captain Jim. At approximately 0230, the master observed that the stern was beginning to sink. He opened the wheelhouse door and told the passenger and the deckhand that it was time to board the life raft. The master proceeded on deck toward the life raft, when the vessel rapidly sank beneath him. The passenger had been standing on the threshold to the wheelhouse, and the deckhand was in the wheelhouse. The master was able to climb into the life raft, and the passenger entered the water as the Captain Jim sank. The passenger swam to the life raft and was assisted aboard by the master. Only 1.5 m of the vessel’s bow remained above water.

At 0232, JRCC Halifax called the master’s cellphone, and the master informed JRCC of the situation. In the darkness, the master and passenger searched for the deckhand in the water without success. At 0234, MCTS Halifax lost the Captain Jim on radar as the vessel sank below the water’s surface (Figure 5). At 0315, the Halifax Harbour pilot boat rescued the master and passenger from the life raft and transported them to Halifax, where they received medical attention. Later that day, at 1105, divers entered the wheelhouse of the sunken vessel, where they found the body of the deckhand and recovered it at approximately 1200. The vessel was recovered on 07 February.

1.4 Environmental conditions

At the time of the occurrence, visibility was clear and it was dark. When the pilot boat arrived on scene, the Halifax weather buoy, located approximately 5 NM from the occurrence site, was reporting winds from the north-northeast at 18 knots, gusting to 21 knots, and seas of 1.3 m. The air temperature was −7 °C, and the water temperature was 1 °C.

1.5 Damage to vessel

The vessel was considered a constructive total loss.

1.6 Vessel certification and inspection

As a commercially operated craft with a gross tonnage (GT) of not more than 15, and carrying not more than 12 passengers, the Captain Jim was required to be registered with Transport Canada (TC) but was not required to undergo periodic inspections by TC or have a certificate of inspection to operate. Under section 106 of the Canada Shipping Act, 2001, a vessel’s authorized representative (AR) is responsible for ensuring that the vessel complies with all applicable regulations.

The Captain Jim had undergone a TC inspection in 2004 in order to voluntarily enrol in the Small Vessel Monitoring and Inspection Program (SVMIP). The vessel was enrolled in the SVMIP in 2005. TC inspected the vessel again in June 2008, when the vessel was undergoing a refit. The refit included an engine overhaul, new fuel tanks, and the addition of the freeing ports. At the time of the inspection in June, the freeing ports had not yet been added to the vessel.

The SVMIP was subsequently replaced by the Small Vessel Compliance Program (SVCP) in 2011, and RMI Marine enrolled the Captain Jim in the SVCP in 2015.

1.7 Small Vessel Compliance Program

The SVCP is a voluntary TC program that provides tools to help ARs (or owners) meet their legal obligations.Footnote2 As part of the SVCP, ARs are required to self-inspect their vessels. The program is available to ARs of non-pleasure vessels up to 15 GT, passenger vessels up to 15 GT carrying 12 passengers or less, and fishing vessels up to 15 GT.

Before a vessel is enrolled in the SVCP, it must be registered with TC. To begin the SVCP process, and upon request, TC provides the AR with a report template and checklist, which offer a simplified explanation of applicable regulatory requirements, such as safety procedures, operations, equipment, maintenance, and emergency preparation. This document is completed to the best of the AR’s knowledge and understanding, although the AR can request the assistance of TC or an independent marine consultant.

Once TC has reviewed the submitted package and concluded that its content is satisfactory, TC enrols the vessel in the SVCP and sends a confirmation letter to the AR. TC also issues a decal indicating compliance, which the AR must post visibly on the enrolled vessel. TC does not routinely conduct inspections when a vessel enrols in the SVCP.

Enrolment is valid for a 5-year period, during which the AR completes an annual report to demonstrate the vessel’s compliance with regulatory requirements. Every 5 years, the AR is required to submit a detailed compliance report.

Statistics provided by TC to the TSB on 09 September 2020 indicated that a total of 28 728 registered commercial vessels of less than 15 GT are operating across Canada. Of these 28 728 vessels, 12 742 are passenger vessels and workboats, and of these, 2047 vessels (about 16%) are enrolled in the SVCP.

1.8 Personnel certification and experience

The master held a Pleasure Craft Operator Card, a Marine Emergency Duties (MED) A2 for small passenger-carrying vessels, and a Restricted Operator’s Certificate (Maritime). He had more than 25 years experience at sea, primarily on tug boats and small commercial vessels operating in the vicinity of Halifax. During that time, he worked mostly as a deckhand and occasionally as a master. He had also worked as a commercial diver in salvage operations, which involved recovering vessels that had partially or completely sunk. He was not the vessel’s regular master, although he had worked for RMI Marine for several years and had served as master of the Captain Jim on occasion.

Under the Marine Personnel Regulations,Footnote3 a master on a vessel such as the Captain Jim is required to hold a Master, Limited for a Vessel of Less Than 60 Gross Tonnage certificate of competency.Footnote4 The master did not have this certificate of competency. The company relied on his experience in lieu of this certificate when he operated the vessel.

The deckhand held a Standard First Aid certificate and a certificate of medical fitness issued by the Diver Certification Board of Canada. The deckhand did not have MED training, although such training was required by regulation.Footnote5

1.9 Stability and buoyancy of decked and undecked vessels

A decked vessel has a fixed watertight deck covering the entire hull above the deepest operating waterline and freeing ports with an area not larger than 4% of the bulwark area. For these vessels, buoyancy and stability are mainly provided by the volume of the hull below the deck, which is designed and maintained to be watertight. When the deck is surrounded by a bulwark, the size, number, and location of freeing ports in the bulwark should be sufficient to drain water freely and quickly overboard to avoid a reduction in stability from free surface effect.

An undecked vessel does not have a watertight deck and relies on bilge pumps fitted below the deck to disperse any water that enters the vessel. Buoyancy and stability are provided by the watertight hull, which extends to the top of the gunwale. Undecked vessels are vulnerable to swamping as a result of water coming over the sides, a risk that may be mitigated by limiting operations to relatively calm waters, incorporating built-in buoyancy to improve survivability, and providing means to efficiently remove any water. If a vessel has sufficient inherent buoyancy,Footnote6 it can swamp without sinking.

The Captain Jim was undecked and did not incorporate inherent buoyancy.

1.9.1 Modifications to undecked vessels

In May of 2007, after consultation with TC, the AR for the Captain Jim installed freeing ports on another vessel owned by RMI Marine, the Lady Shirleen, during modifications to change the Lady Shirleen from an undecked vessel to a decked vessel.

RMI Marine planned to install similar freeing ports on the Captain Jim when it underwent a refit in 2008.Footnote7 RMI Marine had found that the Captain Jim would sometimes take on water over the sides when operating in rough weather and that this water would create a free surface effect before entering the bilge. The freeing ports were installed to allow water to drain overboard. However, the Captain Jim remained an undecked vessel, unlike the Lady Shirleen.

Before installing the freeing ports, the AR provided TC with a list of the items included in the Captain Jim refit. One of the items indicated that RMI Marine planned to install freeing ports on the Captain Jim similar to those on the Lady Shirleen. Subsequently, the AR installed 3 freeing ports on either side of the vessel, which met the size specifications that TC had provided for the Lady Shirleen.

Following the installation of the freeing ports on the Captain Jim, each freeing port was fitted with a securing arrangement that allowed the freeing port to be fastened shut. The practice was to open the freeing ports when the vessel was in rough weather to allow water to drain overboard and to secure the freeing ports closed when the vessel was in calm waters.

Reserve buoyancy and stability are a function of the freeboard, measured to the position of the lowest downflooding point. Reducing the freeboard or the height of the downflooding point reduces a vessel’s reserve buoyancy and stability. The Captain Jim was designed to have a watertight hull that provided an average aft freeboard of 0.9 m. However, when the Captain Jim was operated with its freeing ports open, the average aft freeboard was 0.1 m. After the Captain Jim was modified, its stability was not reassessed.

1.10 Post-occurrence examination

After the Captain Jim was raised, the vessel’s hull was examined and was found to be structurally intact. The aluminum flaps on all of the freeing ports were still secured by the securing arrangements, with the exception of the forward starboard freeing port. The scuppers were found to be open. No other areas were identified that could allow for unexpected ingress of water.

The 3 on-board pumps were examined, and the 2 electric bilge pumps were removed from the vessel and sent to the TSB Engineering Laboratory for testing.

1.10.1 Electric bilge pumps

Testing indicated that both of the pumps were fully functional and met the requirements of the Construction Standards for Small Vessels for flow rateFootnote8 when the engine was running. The aft pump had a discharge flow rate of 4509 L/h and the forward pump had a rate of 4180 L/h.

1.10.2 Engine-driven pump

Although designed as a firefighting pump and used as a washdown pump, the engine-driven pump could be configured for use as a bilge pump. To do so, the crew had to manually change over the suction via a changeover valve in the engine compartment. As well, the hatch cover and coaming for the engine compartment had to be removed and a hose had to be attached to a 1.5-inch coupling on the pump in order to discharge the water over the vessel’s side. The pump was rated for a discharge flow rate of 27 085 L/h at 2000 rpm.

RMI Marine considered configuring the engine-driven pump for use as a bilge pump to require 2 people. There was no formal guidance available to the crew on how to configure the engine-driven pump for use as a bilge pump.

1.11 Emergency management

The master and crew on board a vessel must be prepared to respond to emergency situations that could arise. For small commercial vessels, TC has developed a guide Footnote9 that, among other things, advises operators of passenger-carrying vessels to take the following actions before departure to maximize safety on their vessels:

- Check various components of the vessel, such as the engine, equipment, bilges, drain holes / scuppers, and navigation lights.

- Ensure personal protective equipment is available and used as needed.

- Ensure that there are enough lifesaving appliances of appropriate size for everyone on board.

- Conduct a standard passenger safety briefing to discuss personal protective equipment use, the location and deployment of lifesaving equipment, and the roles and responsibilities of crew and passengers during emergencies.

1.12 Safety management system

The main objective of a safety management system (SMS) is the safe operation of a vessel to ensure the safety of crew and passengers, and to avoid damage to property and the environment. An SMS involves individuals at all levels of an organization and promotes a logical approach to hazard identification and risk assessment and mitigation. It includes a set of documents that a vessel owner or AR prepares with their masters and crew to establish procedures, plans, and instructions, including checklists as appropriate.

The International Safety Management Code (the ISM Code) provides an international standard for the safe operation of ships and prevention of pollution. Chapter IX of the International Convention for the Safety of Life at Sea, 1974 requires certain ship operators to adopt an SMS that complies with the ISM Code.

Canada’s Safety Management Regulations require 3 types of Canadian vessels that operate on international voyages to adopt an SMS Footnote10 that complies with the ISM Code:

- Passenger ships, including passenger high-speed craft

- Oil tankers, chemical tankers, gas carriers, bulk carriers, and cargo high-speed craft of 500 GT or more

- Other cargo ships and mobile offshore drilling units of 500 GT or more

TC is in the process of amending the Safety Management Regulations. The proposed amendments will align requirements for larger vessels and those vessels that TC considers to be high risk with the ISM Code. These vessels will be subject to annual inspection and approval by a recognized organization. Smaller vessels (15 GT or less), such as the Captain Jim, will need to put in place an adapted domestic SMS and will be subject to TC’s standard risk-based oversight regime.

The Captain Jim did not operate under an SMS, nor was it required to under current regulations. However, the Captain Jim was subject to section 106 of the Canada Shipping Act, 2001, which requires the AR to ensure procedures are developed for the safe operation of the vessel and for dealing with emergencies and to ensure that passengers and crew receive safety training.

To manage safety, RMI Marine had developed a company safe work manual and a vessel safety plan.

1.12.1 Company safe work manual

The safe work manual covered the company’s safety policy, responsibilities, hazard assessments, and safe work policies. It also included a pre-departure checklist and vessel inspection form.

The pre-departure checklist provided to the crew of the Captain Jim prompted them to test the bilge pumps and check the following:

- Vessel electronics

- Amount of fuel and oil on board

- Vessel lighting

- Number of personal flotation devices and lifejackets on board

- Number of fire buckets on board

- Fire extinguishers and flares

The vessel inspection form was to be used every 2 weeks for a routine maintenance inspection.

Before the occurrence, the masters of the Captain Jim filled out the pre-departure checklist intermittently, sometimes opting to do an informal mental run-through of the checklist instead of filling it out. The crew did not complete the pre-departure checklist before the vessel departed on the occurrence voyage, nor did it test the electric bilge pumps or the engine-driven pump.

Normally, any completed pre-departure checklists and vessel inspection forms were kept on board. The company did not conduct audits to ensure that these forms were being completed.

1.12.1.1 Vessel safety plan

The vessel safety plan for the Captain Jim included the pre-departure checklist discussed above and instructions to familiarize crew and any passengers on board with the vessel’s safety features, such as the life raft, fire extinguishers, and the engine-driven firefighting/washdown pump. The vessel safety plan provided guidance to the crew for specific emergencies, such as fire, sinking, person overboard, loss of steering, and pollution. The guidance for sinking was as follows:

- Have all passengers go to muster point and adorn [sic] lifejackets

- Relay distress alert on VHF

- Prepare life rafts for deployment

- Have pyrotechnics available

- If situation cannot be controlled, abandon vesselFootnote11

The vessel safety plan was posted in the wheelhouse.

1.13 Decision making

Situational awareness and performance biases are factors that can affect decision making and effectiveness in an emergency.

1.13.1 Situational awareness

People working in operational environments make decisions by building a mental model of their operational environment. This mental model is supported by an individual’s situational awareness, which refers to “the perception of elements in the environment within a volume of time and space, the comprehension of their meaning, and the projection of their status in the near future.”Footnote12 Situational awareness is a critical component of decision making and involves information-processing stages. Shortcomings during these stages may result in an incomplete or inadequate perception of the situation. A person’s knowledge, experience, training, and fitness for duty can also influence situational awareness.

A master is constantly perceiving various factors as a voyage unfolds, developing an understanding of their meaning, and predicting the effects these factors will have on the outcome of the voyage. These processes are driven by the information available to the master, but also by the overriding context, goals, environment, procedures, training, experience, knowledge, technique, level of stress, level of fatigue, and availability of time. These processes create a mental model of an unfolding situation.

1.13.2 Plan continuation

Plan continuation is a human performance bias that can occur when a situation is considered to have a good probability match and the diagnosis is assumed, sometimes at the expense of a balanced review of another possible diagnosis. Plan continuation may result in an operator attempting to resolve an abnormal situation or emergency by adhering to a chosen course of action despite indications that an alternative approach is actually required. The bias is shaped by the context in which the crew operate, the resources available, and their operational goals.

The bias can be set and encouraged by the initial presence of strong and persuasive cues that are perceived to support the chosen course of action. The effect of the bias is not easily recognizable to the operator, in part because abnormal events surrounding an emergency can develop slowly and ambiguously. The bias can result in the operator believing that actions taken to address an emergency are effective and the situation is under control, even in the presence of cues suggesting that it is not. Human factors research has indicated that “[e]ven more important than the cognitive processes involved in decision making, are the contextual factors that surround people at the time.”Footnote13

Ambiguous cues indicating that alternative actions should be taken may not be compelling to the operator at the centre of an emergency. As time progresses in a complex environment, other critical tasks are added to the operator’s cognitive workload, which may reduce the operator’s capacity to detect important cues that the current plan is ineffective or risky. The narrowing of attention in a stressful situation may support plan continuation, as a high workload and time pressures are not conducive to pausing to consider alternatives.

1.14 Previous recommendations

1.14.1 Safety management systems

Following an occurrence on 23 June 2002 in which the amphibious passenger vehicle Lady Duck took on water and sank in the Ottawa River, causing the death of 4 passengers, Footnote14 the Board recommended that

the Department of Transport take steps to ensure that small passenger enterprises have a safety management system.

TSB Recommendation M04-01

In its latest response to this recommendation, issued February 2021, TC indicated that the proposed amendments to the Safety Management Regulations will expand both SMS and oversight requirements to all domestic passenger vessels. As a result, in March 2021, the reassessment of TC’s response to this recommendation was rated as showing Satisfactory Intent. The TSB’s latest reassessment of this response, as well as previous responses and assessments, are available on the TSB website. Footnote15

1.14.2 Passenger and crew evacuation

Following the occurrence involving the Lady Duck, the Board also recommended that

[t]he Department of Transport ensure that small passenger vessels incorporate sufficient inherent buoyancy and/or other design features to permit safe, timely and unimpeded evacuation of passengers and crew in the event of an emergency.

TSB Recommendation M04-03

In response to Recommendation M04-03, TC required vessels of 6 m or less to take measures to ensure they remain afloat if swamped. For existing uninspected vessels more than 6 m long and 15 GT or less, such as the Captain Jim, TC introduced no new requirements but pointed out that the Canada Shipping Act, 2001 requires owners and masters to use all reasonable means to ensure that their vessels are seaworthy. At the time, TC’s response was considered to substantially reduce the safety deficiency. As a result, in November 2006, the reassessment of the response to this recommendation was rated as Fully Satisfactory.

The TSB’s latest reassessment of this response, as well as previous responses and assessments, are available on the TSB website. Footnote16

The TSB notes that, even when a recommendation is rated as Fully Satisfactory, there may continue to be residual risk. In this case, a risk remains for existing uninspected vessels more than 6 m long and 15 GT or less that do not have sufficient inherent buoyancy and/or other design features to permit safe, timely, and unimpeded evacuation of passengers and crew in an emergency.

1.15 TSB laboratory reports

The TSB completed the following laboratory report in support of this investigation:

- LPO41/2019 – Bilge Pumps Float Switch and Fuse Analysis

1.16 TSB Watchlist

The TSB Watchlist identifies the key safety issues that need to be addressed to make Canada’s transportation system even safer.

Safety management and regulatory surveillance are Watchlist 2020 issues. TC does not require most commercial operators to have a formal SMS. As this occurrence demonstrates, vessel operators that are not required to have a formal SMS may not be managing all risks effectively.

| ACTIONS REQUIRED

Safety management will remain on the Watchlist for the marine transportation sector until

|

As well, as this occurrence demonstrates, even though a vessel is voluntarily registered in the SVCP, TC may not be aware that a vessel has been modified in a way that affects its watertight integrity.

| ACTIONS REQUIRED

Regulatory surveillance will remain on the Watchlist for the marine transportation sector until TC provides more oversight of the commercial vessel inspection process by demonstrating that its surveillance and monitoring are effective in ensuring that ARs and recognized organizations are ensuring compliance with regulatory requirements. |

2.0 Analysis

The investigation determined that sea water entered through openings in the Captain Jim’s hull, eventually causing the vessel to sink. The analysis looked at modifications that affected vessel stability, factors that influenced decision making, and the company’s management of safety.

2.1 Modifications that affect vessel stability

Certain modifications to a vessel, such as the addition of freeing ports, can have substantial impacts on watertight integrity and stability. Effective management of safety requires an assessment of any vessel modifications.

The Captain Jim’s freeing ports were added during a vessel refit in 2008 and were modelled on freeing ports that had been approved for the Lady Shirleen’s refit. However, during the Lady Shirleen’s refit, the vessel was modified from an undecked vessel to a decked vessel. This meant that the Lady Shirleen’s buoyancy was provided by the volume of watertight hull below the watertight deck; the addition of freeing ports above the watertight deck did not affect its watertight integrity.

By contrast, as an undecked vessel, the Captain Jim relied on freeboard provided by its watertight hull for buoyancy and stability. Without the freeing ports, the Captain Jim’s freeboard extended to the top of the gunwale. However, when the freeing ports were added, the vessel’s average aft freeboard was reduced from 0.9 m to approximately 0.1 m. The addition of freeing ports to the Captain Jim’s hull reduced the vessel’s freeboard and rendered it vulnerable to water ingress. The Captain Jim was an undecked vessel, and so any water that entered through the freeing ports accumulated on deck, passed down through the non-watertight hatches in the deck, and entered the vessel’s bilge.

At some point on the return voyage to Eastern Passage, unbeknownst to the crew, sea water began entering the vessel through an open freeing port. The amount of water that entered the hull exceeded the capacity of the bilge pumps and flooded the area below the deck.

Although RMI Marine installed the freeing ports on the Captain Jim, and identified the plan to do so to Transport Canada (TC), neither party completed an assessment of the possible safety implications of shipping more water on the deck than the bilge pumps were capable of removing. This meant that RMI Marine was unaware of the adverse effects that the freeing ports had on the Captain Jim’s stability. If vessel modifications are not adequately assessed for their safety implications, there is a risk that those modifications may unknowingly compromise a vessel’s stability, affecting the safety of the vessel’s crew and passengers.

2.2 Decision making

Situational awareness and performance biases are factors that influence decision-making processes. A person’s knowledge, experience, training, and fitness for duty can also influence situational awareness and decision making.

Shortly after the high-water bilge alarm sounded and water was observed accumulating on deck, the master continued the voyage, since the vessel was close to calm water on the way to port and both electric bilge pumps were operating.

A short time later, the master observed that the securing arrangement for the starboard forward freeing port was not in place and that wave action was causing surges of water to enter the vessel through the open freeing port, increasing the amount of water on deck. The master then decided to continue the voyage toward shallow water. This decision was influenced by a number of factors. Reaching shallow water would provide an opportunity to intentionally ground the vessel if necessary. The vessel had a bow-up attitude, remained steerable, was maintaining a speed of around 10 knots, and did not have a list. The master had previous experience in salvage operations in which vessels had taken on substantial amounts of water but had not sunk, and the master may have applied these experiences to the Captain Jim. As well, with the deckhand injured, the master did not have a crew member to assist with troubleshooting the water ingress or plugging the aft scuppers. Furthermore, the master did not consider it safe to task the passenger with navigational duties.

In this occurrence, the master’s decision to attempt to return to calmer waters was influenced by his many years of experience at sea. However, this experience did not provide him with the technical proficiency needed to fully understand the stability implications of the water ingress and therefore appreciate the urgency of the unfolding situation.

The master’s focus on continuing the voyage was consistent with plan continuation bias. As the voyage continued, the unmitigated water ingress resulted in water overwhelming the vessel’s engine and batteries, which caused the bilge pumps to stop working. Without operational pumps and inherent buoyancy, and with the aft scuppers open, the vessel continued to take on water and gradually sink by the stern until the weight of the water exceeded the buoyancy of the vessel, and the vessel sank rapidly.

Although the life raft was inflated and alongside the vessel, the crew had been taking shelter in the wheelhouse to reduce their exposure to the elements. Because the vessel sank rapidly and the crew were in the wheelhouse, there was insufficient time for everyone to abandon into the life raft; as a result, the passenger entered the water and the injured deckhand drowned.

2.3 Safety management

A safety management system (SMS) provides a formal, documented, and systematic approach to help vessel operators manage risk. Risk management under an SMS is a continuous process of identifying hazards and analyzing, mitigating, and following up on existing and potential risks. It must involve individuals at all levels of an organization. An SMS can be tailored to the needs of the operation, and even small companies benefit from having safety processes in place to manage risk. It is important that the SMS guidance be adhered to at all times. A company can ensure that guidance within its SMS is being followed through regular audits.

Although small vessels operating as passenger vessels, such as the Captain Jim, are not required to have a formal SMS, TC regulations require authorized representatives to develop procedures for the safe operation of the vessel and for dealing with emergencies and to ensure that passengers and crew receive safety training. However, there is no regulatory requirement for processes to ensure the ongoing identification of hazards and the assessment and mitigation of risks. Therefore, TC regulations do not lay out a framework for safety management equivalent to that of an effective SMS.

In the absence of a requirement for a formal SMS, RMI Marine, like many other small vessel operators, attempted to manage risk through guidelines, policies, plans, and checklists. However, the investigation identified gaps that had consequences in this occurrence. For example, there was no guidance for crew to ensure all potential points of water ingress were identified and mitigated before departure and to ensure that crew were aware of all available means to dewater the vessel.

The investigation also identified that the company did not have a method for ensuring that vessel modifications that could affect stability were assessed, that operators and crews were familiar with stability principles as they applied to company vessels, and that all operators held the necessary certification. Finally, RMI Marine did not audit its safety management processes, nor did it have a method to ensure that the pre-departure checklist and vessel inspection form were used.

If a company’s processes for managing safety are missing key elements, and there is no requirement for a formal audited SMS, there is a risk that vessels will be unknowingly operated in a manner that compromises the safety of those on board.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts or safety deficiencies that were found to have caused or contributed to this occurrence.

- The addition of freeing ports to the Captain Jim’s hull reduced the vessel’s freeboard and rendered it vulnerable to water ingress.

- At some point on the return voyage to Eastern Passage, unbeknownst to the crew, sea water began entering the vessel through an open freeing port. The amount of water that entered the hull exceeded the capacity of the bilge pumps and flooded the area below the deck.

- With the deckhand injured, the master did not have a crew member to assist with troubleshooting the water ingress or plugging the aft scuppers.

- The master’s decision to attempt to return to calmer waters was influenced by his many years of experience at sea. However, this experience did not provide him with the technical proficiency needed to fully understand the stability implications of the water ingress and therefore appreciate the urgency of the unfolding situation.

- As the voyage continued, the unmitigated water ingress resulted in water overwhelming the vessel’s engine and batteries, which caused the bilge pumps to stop working.

- Without operational pumps and inherent buoyancy, and with the aft scuppers open, the vessel continued to take on water and gradually sink by the stern until the weight of the water exceeded the buoyancy of the vessel, and the vessel sank rapidly.

- Because the vessel sank rapidly and the crew were in the wheelhouse, there was insufficient time for everyone to abandon into the life raft; as a result, the passenger entered the water and the injured deckhand drowned.

3.2 Findings as to risk

These are conditions, unsafe acts or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- If vessel modifications are not adequately assessed for their safety implications, there is a risk that those modifications may unknowingly compromise a vessel’s stability, affecting the safety of the vessel’s crew and passengers.

- If a company’s processes for managing safety are missing key elements, and there is no requirement for a formal audited safety management system, there is a risk that vessels will be unknowingly operated in a manner that compromises the safety of those on board.

4.0 Safety action

Safety action taken

Following the occurrence, RMI Marine took steps to ensure that only Transport Canada–certified personnel operate its vessels and that its vessels are inspected and function-tested by company personnel on a quarterly basis. RMI Marine also implemented a new mobile app so that completed forms and records are automatically transmitted to the office. Finally, RMI Marine implemented regular training on the procedure to configure the engine-driven pump for use as a bilge pump.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .

Appendices

Appendix A – Layout of the Captain Jim

Source: TSB